Monolith at Automotive Testing Expo Europe 2023

Learn how SaaS AI software is used by automotive engineers

Stuttgart, Germany

June 13, 14, 15, 2023

Booth 1228, Hall 10

Presentation: Four examples of AI applications by engineers in R&D

Wednesday, June 14 - Hall 10 - afternoon session @ 14:40

AI is revolutionising the way products are tested and developed. Richard Ahlfeld, CEO and founder of Monolith, will discuss how AI is changing the engineering testing landscape, including the use of predictive analytics to make better data-driven decisions to avoid product launch delays, improve product quality, reduce costs, and ultimately speed up time-to-market.

Additionally, the talk will address the four key areas where AI has a significant impact on product development and can mitigate the risks of product failures, such as system calibration, root-cause analysis, virtual testing, and test campaign optimisation.

Meet our team

Have technical demos, chats & consultations at our booth

About Automotive Testing Expo:

Automotive Testing Expo is the world’s leading international expo for every aspect of automotive testing, development and validation technologies, taking place every year in Detroit, Shanghai and Stuttgart. In Europe, as elsewhere, it is the leading event for the technologies and services in ADAS and autonomous vehicle testing, electric and hybrid powertrain testing, battery and range testing, EMI and NVH test and analysis and the full spectrum of test and validation technologies for full-vehicle, component and systems development.

About Monolith

We enable engineers all over the world to:

- Understand physically intractable problems

- Fully explore multiple virtual test scenarios

- Reduce costs and time investment throughout the whole R&D cycle

- Increase confidence in predictions & recommendations on which tests to run next

Trusted by

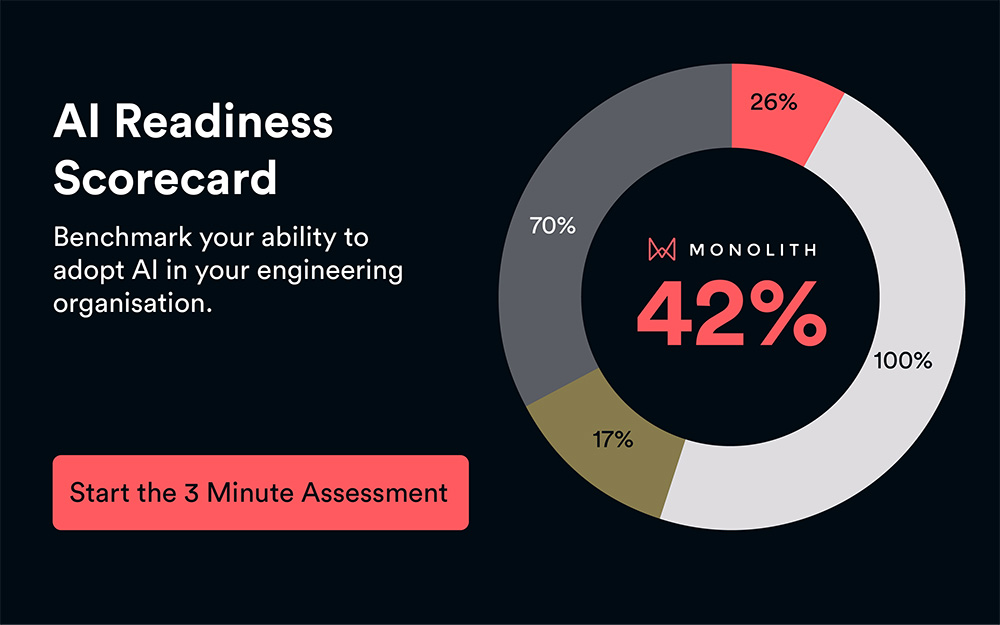

Are you ready for AI?

AI readiness scorecard

Complete Monolith's 3-minute assessment to develop an understanding of your organisation's readiness for AI, and which areas can benefit from the implementation of AI through an in-depth report sent directly to you.

Four ways to use AI to cut validation costs

Build shorter test plans, create fewer prototypes, find errors faster, and validate designs more quickly using AI-based self-learning models.

1. Avoid wasted tests

To avoid downstream issues, your engineers must tediously inspect test data for errors. One failed sensor or wiring malfunction can render thousands of dollars in testing useless.

- Prepare your data for optimal AI performance

- Catch bad data now so you avoid re-engineering later

- Find outliers in your test data fast with intuitive visualisation

2. Reduce the tests you run

Test too much and you waste time confirming what you already know. Test too little and risk missing performance issues. Schedule, quality and your career depend on finding the balance.

- Run the most important tests and skip the rest

- Optimise resources spent on costly test rigs and facilities

- Validate your designs faster with fewer prototype iterations

3. Know the critical parameters to test

Product design issues during validation risk launch delays and lost market share. Pressure on engineers is high to identify critical parameters causing failure, quickly analyse the root cause, and predict how the product will perform in changing conditions.

- Predict what design changes will most likely fix the failure

- Identify components causing sub-optimal performance

- Avoid long delays and uncertainty in the validation process

4. Test for thousands of conditions

Designing highly complex, non-linear systems that must meet stringent performance standards is challenging. Predicting which combination of inputs will deliver the optimal output, in all operating conditions, is next to impossible.

- Calibrate complex dynamic systems

- Ensure your system performs to spec in all conditions

- Find best-fit values across 1000's of inputs and conditions