Packaging sustainability through AI

The growth of sustainable packaging solutions is not a new event but has accelerated in the past decade as awareness of environmental issues has drastically increased.

With that came the rise in demand for household waste reduction, an increase in recyclability, especially plastic packaging as well as reducing carbon emissions and other pollutants.

According to a 2018 Tetra Pak Index survey, 80% of consumers in South Korea – the most developed country for e-commerce – and 74% in the US say they would avoid products that are packaged in several layers, for environmental reasons.

Such consumer attitudes have been growing in the EU as well. As a result, in the European Commissions’ 2021 Work Programme, sustainability features heavily on the agenda.

The 2021 work programme is designed to make Europe healthier, fairer, and more prosperous while accelerating its long-term transformation into a greener economy, fit for the digital age. It sets out a list of actions for the upcoming 12 months that fit with its commitments.

Effective 1 January 2021, a levy composed of a share of revenues from national contributions calculated on the weight of non-recycled plastic packaging waste with an effective rate of €0.80 per kilogram.

Anticipating the change in consumer attitudes and potential likely levies, many brand owners have played an essential role in the push for more sustainable packaging.

Some are committing to being more environmentally-friendly by implementing an eco-friendly packaging policy, which includes the design and production of packaging.

- Johnson & Johnson - All J&J brands will switch to using 100% recyclable, reusable or compostable plastic packaging by 2025.

- Amazon - Already reduced outbound packaging by 33% (915,000 tonnes) and plans to reach net zero carbon by 2040.

- Estée Lauder companies - By 2025, 75 to 100% of Estée Lauder packaging will be recyclable, refillable, reusable, recycled or recoverable.

- L'Oreal - By 2030, L'Oreal will reduce plastics by 50% per finished product and 100% of all plastics used in packaging will be either from recycled or bio-based sources.

We have shared four brand owners who collectively own over 70 brands, and they are just the major ones who have made commitments to change their approach to packaging and have already demonstrated actual steps to accomplishing their sustainability commitments.

The packaging design process and sustainability

Typically, the focus has been on the consumer to recycle packaging responsibly. They are tasked with finding ways to recycle or reuse undesired materials, but this is where the industry needs to change as up to 80% of products’ environmental impacts are determined at the design phase (Publications Office of the European Union, 2014).

Up to 80% of products’ environmental impacts are determined at the design phase.

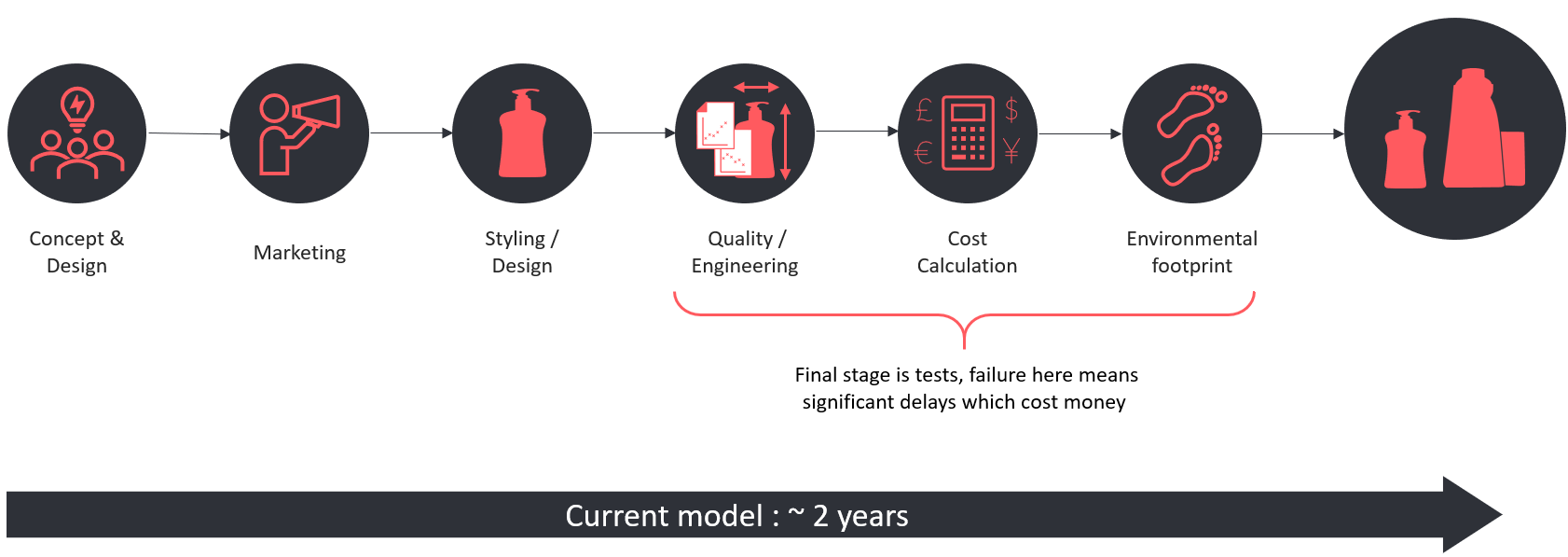

The current way we design packaging needs to fundamentally change to create sustainable products and also to optimise the development process as it is quite lengthy.

Currently, the carbon footprint is normally calculated near the end of the process, which is one of the reasons why creating eco-friendly solutions is slow to enter the market.

Also, the smallest product change can create a need for new packaging: new product variations, materials, and rebranding.

Technical and creative information collides with file formats whenever packaging is involved. Sustainable packaging designers are asked to localise designs for multiple markets and change particular elements creating many iterations of the same basic package design.

That’s a lot of moving parts to manage and coordinate for friendly packaging materials and design verification.

Take the example of a bottle, it can be any type of bottle, a sports water bottle or a wine bottle and a retailer wants a manufacturer to create a bottle that won't topple easily.

Simulation engineers at the manufacturer will use advanced tools to predict the chances of the bottle being knocked over and they can usually do this with a 10-20% margin of error.

The simulation tool will factor in the bottle size, shape, thickness, and density of packaging materials used and the liquid content's density, but it will require multiple simulations to reduce the error margin and if a small change is made in the product then the entire process needs to be repeated.

This is where artificial intelligence can help speed up the development process and to create more sustainable packaging and ultimately decrease a company's carbon footprint.

With the right tool, manufacturers can create an AI solution that understands design and predict with much higher accuracy whether this bottle will topple over or not.

When a product change is necessary, fewer simulations would be required to predict the result. The same tool can be used to predict how to achieve the same durable sustainable packaging design with less material to ensure less plastic is introduced into the environment or even if using an entirely different packaging material would get similar or better results.

Not all AI is created equal

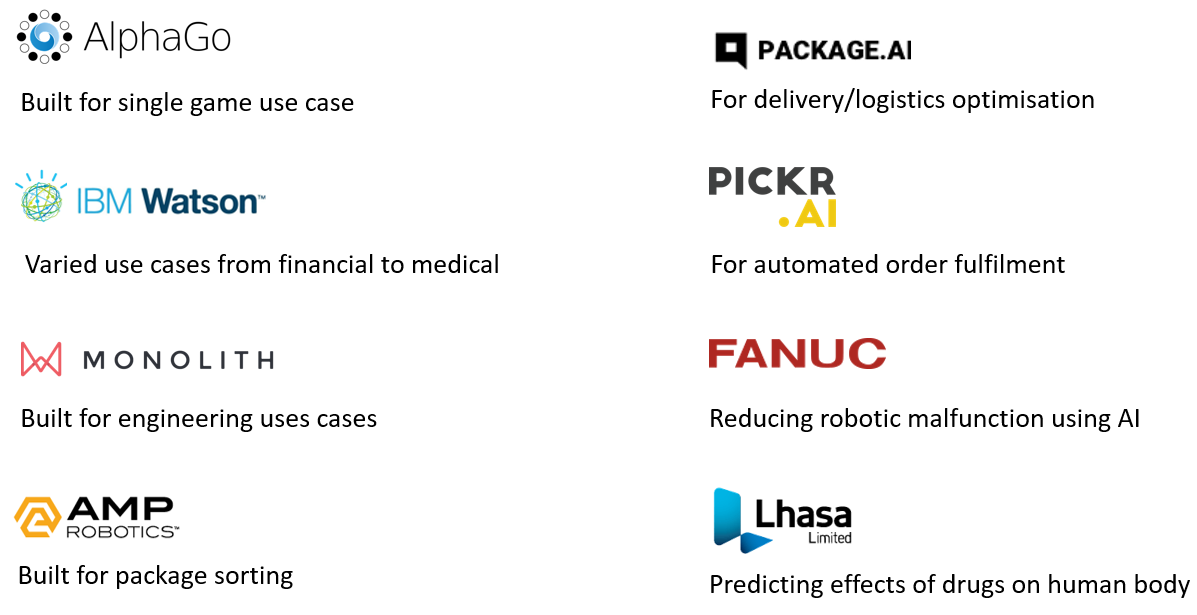

Artificial intelligence and machine learning solutions are already being used by packaging manufacturers and retailers like Amazon or Tetra Pak to reduce packaging materials, and increase the use of reusable packaging and recycled materials, while without sacrificing quality.

However, picking the right AI solution is important as different platforms solve different sustainable packaging problems.

Some are good at sorting recycled goods, and vision systems can be used to inspect the quality of packaging and find any flaws but at the moment there are very limited choices to pick a platform that can help you create sustainable packaging.

This is where Monolith AI comes in to improve sustainable solutions for packaging products and their designs.

Popular AI platforms are currently used throughout the packaging industry.

Monolith AI is used by sustainable packaging manufacturers and retailers to not only develop more sustainable packaging for products but also to predict the performance of each design.

Using the same variables such as the liquid density, thickness of the material etc, our AI solution can predict the performance and help you decide on the right sustainable packaging design faster.

Monolith AI: A solution to sustainable packaging

Artificial intelligence has the potential to empower just about everyone and any department in the packaging sustainability development decision value chain to contribute and improve the end result.

However, before deciding on deploying a sustainable packaging solution within your business, spend some time considering the following:

- Structured data - To get down to the 'hows' and 'whys' of product design and performance. What type of data are you currently retaining when designing and testing products?

- Use cases - To benefit from machine learning, you need a clear understanding of your business problems. These problems should be actual business problems that would justify investing in an Artificial Intelligence or Machine Learning solution.

- Not all AI is created equal - Ensure that the AI solution you like will fit the use cases you have identified and that it can scale easily as your business grows