The automotive industry has adopted a great number of Artificial intelligence innovations. From predictive maintenance of vehicle fleets to autonomous cars. AI is demonstrating it can transform customer experiences and provide a much-needed productivity boost.

AI holds the key to a new future of value for the automotive industry. While popular attention is focused on the use of AI in autonomous cars, the industry is also working on AI applications that extend far beyond – supply chain, predictive maintenance, customer experience, and mobility services among others

Manufacturers use many methods to assess a new car's performance. At each development phase, different methods are used: CFD simulations before any prototype is produced, tunnel experiments, and eventually, track testing. Track testing provides the most accurate and relevant performance results. The initial tests are used to direct development towards designs that are most likely to have the best performance in steady-state track testing.

Steady-state track testing

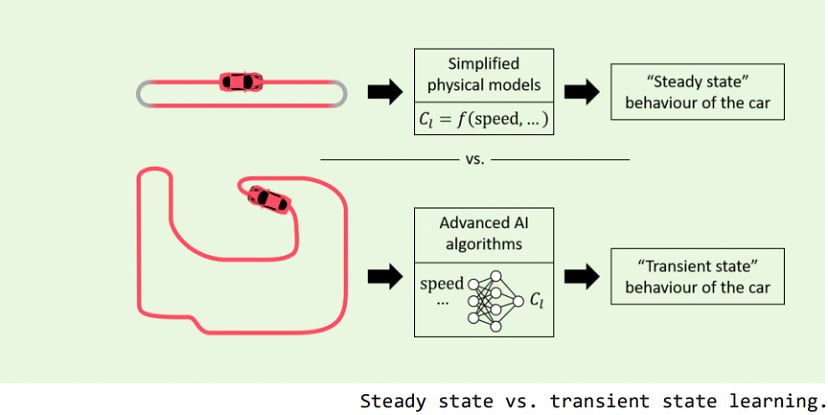

Track testing provides large datasets from sensors measuring acceleration, velocity, temperature, and more. Understanding the underlying performance of the car in this “dynamic” environment is extremely difficult. The complex interaction of all the vehicle components, weather conditions, track conditions, and driving style, makes for a huge set of complex high-dimensional data. Instead of testing the dynamic response of the car, some manufacturers test in a “steady-state” manner – for example, driving in a straight line at constant speeds. This makes it easier to extract the car performance from the sensor data.

Steady-state testing has several limitations. First, most tests are performed on real tracks to assess other aspects of the car, such as the cooling system or the comfort of the driver. While at the track, separate tests are performed to gather data for the steady-state response of the car. Secondly, the resulting performances measured by these steady-state tests are often too simplistic to model the full dynamic response.

Transient testing

A more elegant solution is to use AI algorithms to learn the performance of the car in “transient tests”. These dynamic-learning algorithms learn the physics of the car by using all the available data from the normal real track tests, without the need for separate steady-state tests. The trained models can be used to predict the dynamic behaviour of the car for unseen cases, such as on another track.

Dynamic models can predict complex behaviours that steady-state models cannot answer. For instance, whereas steady-state models can only answer questions such as “what is my down force at 60mph?”, a dynamic-learning model can answer: “how is the down force affected if I accelerate from 30 mph to 40mph while taking a sharp left corner?”. Moreover, this test can be combined with other tests that are required by legislation, saving money and weeks of testing time.

With Monolith AI, a few consecutive tests can provide sufficient data for an insightful machine learning expert system. By using several years of existing data, Monolith can immediately help engineers shorten their development cycles. Different departments can then train and run advanced deep learning models, enabling them to forecast how their own decisions will affect other departments involved in the production cycle.